OPPO Find N2 Flip undergoes crazy stress-test to assure longevity

Can your smartphone survive these harrowing stress-tests?

400,000 folds, 200,000 buttons mashed, and surviving 1.5 meter drops more than 30 times. That’s how much the OPPO Find N2 Flip, OPPO’s latest luxury flagship device has to endure before they make it out of the production line.

We recently just came from the OPPO Industrial Park in Shenzhen, China, where they assemble their smartphone devices, fabricate PCB (Printed Circuit Boards), and conduct numerous quality testing, among the myriad of other tech wizardry that the brand does.

The last time we were here was over 6 years ago and back then the entire complex was still being built with only 1 or 2 buildings standing. Obviously, the brand has expanded by then, and we’re happy to be visiting their facilities (in its entirety) once more during this year’s OPPO Foldable Tech Tour where the brand invited various media groups within the APAC region.

With hyper-lens focus on the OPPO Find N2 Flip , we were treated to a line production display of assembling what currently is the benchmark for amazing flip smartphone device, and a peek into the numerous testing the product has to go through before they even make it into the assembly line for mass production.

Because the Find N2 Flip is a new device line from the brand, there are more tests done versus the regular candy-bar type smartphones. And, as OPPO has always been doing, they go above and beyond industry standard to ensure that each unit a customer receives has the highest grade quality that the company could provide.

There are two main physical test types done on most (if not all) devices from the brand: mechanical testing, and environmental testing.

Both test recreates scenarios of everyday use, potential mishaps, and various environmental and temperature challenges that the smart device could face – even extreme ones.

Flip, Drop, Bend, Twist – More Tests Done on the Find N2 Flip

For their mechanical drop test, OPPO repeatedly drops their test devices up to 1.5 -1.8 meters high, a lot higher than the 1 meter test set by industry standards. For OPPO the device must survive the fall ensuring internal structures are intact and usable still. The test is conducted 12 to 32 times.

Then there’s the tumble test where phones are thrown around in a giant metal “tambiolo” simulating when you lazily sling your phone on your bed…and miss. 😅 The devices are placed in a rotating barrel where the phones slide down and collide against steel panels and continuously slides down further as the barrel rotates again, and again, and again….to the tune of about 150 turns.

For button-mashers out there, the button stress test checks the functionality of physical buttons (like power buttons, volume rocker, and fingerprint button). The power button is pressed 200,000 times, volume rocker about 100,000 and the fingerprint button a whopping 500,000 times. According to OPPO this is beyond the average times these buttons will be pressed in the unit’s lifecycle.

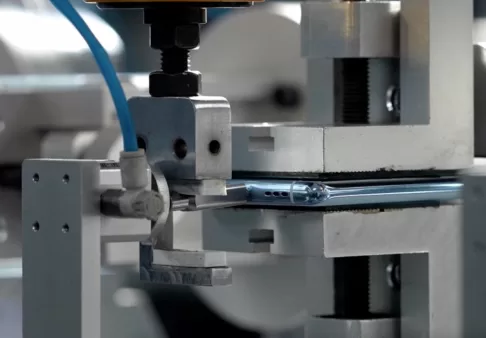

There are various more tests like the soft-press test which simulate the product’s resistance to pressure when a user bends down and the unit is inside their jean pockets, USB bend test which checks the reliability and stability of the USB port, Plug and Unplug test (for USB and Audio Jack), Twist Test, Micro-drop test among other things.

But for the OPPO Find N series specifically, they crafted the Folding Test where the units like the OPPO Find N2 Flip are folded 400,000 times, twice more than what the OPPO Find N2 Fold had to go through.

Testing the Elements

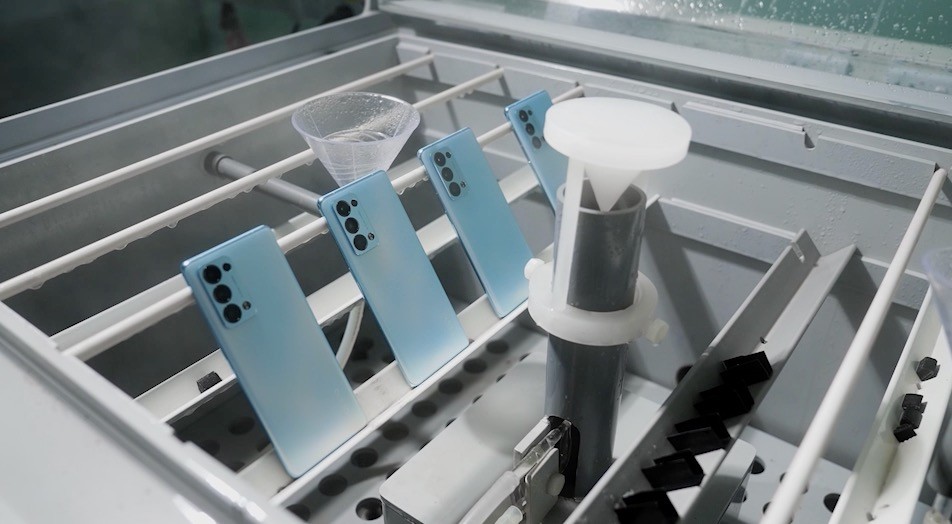

Lastly, the environmental test puts the units like the Find N2 Flip, in extreme hot, cold, or damp environment. The Waterproofing Test subjects the smartphone to micro jets of water shoots all around the phone to test the phones in IPX2 and IPX4 conditions.

Spray Test aka the surface corrosion test where the units are sprayed with a salt solution and stored in a hot and humid environment before checking for any signs of damage. As always, the Fold, having 2 parts, is given another Foldable Test but this time with extreme environmental factors.

Spray Test where phones are sprayed with salt solution and enclosed in humid areas to check for corrosion

Since 2008 when OPPO established the Quality Engineer (QE) Reliability Lab, they have been steadily improving and optimizing testing processes to ensure that products that will come out of OPPO is up to the highest of standards possible.

If you’re wondering how many units per phase are tested, the engineers at OPPO mentioned they test about 500 units per product development phase. This includes pre-development, sampling phase, all the way up to mass production. These multiple stress-tests are conducted so that calibration and optimization are done on the units to ensure the product’s longevity.

With more than a dozen test carefully concocted by OPPO, it’s nice to know that the smartphones we’re getting have passed through rigorous stress-testing before they land on our hands.

And for those still skeptical about the folding tech on smartphones, particularly the OPPO Find N2 Flip, know that OPPO is hard with testing and constant optimization on both the hardware and the software front. We recently had an update on the ColorOS 13 (running on Android 13) — with the inclusion of cover screen support for a known music app and an assurance of more app supports in the very near future.

For more on the OPPO Find N2 Flip, check out their official page and social media channels.